Yeloworld Has Completed a B+ Round of Funding Exceeding RMB100 Million | It Is Anticipated that Yeloworld Will Complete Its Shareholding Reform in 2024 and Formally Prepare for Its Initial Public Offering (IPO)

Recently, Shanghai Yeloworld Technology Co., Ltd. (abbreviated as “Yeloworld”) announced the completion of its Series B+ funding round, which exceeded RMB100 million. Prior to this, Yeloworld had received investments from institutions such as Sinopec, Wanhua Chemical, and GL Ventures.

Yeloworld stated that the funds from this round of financing will be allocated to establish a plastic circular economy focused on intelligent packaging production, operation, recycling, and regeneration. The funds will be specifically allocated to upgrading the packaging product line, expanding packaging production and plastic recycling capacities, establishing smart logistics and recycling networks, and advancing digitalization and intelligence throughout the industry chain.

Founded in 2018, Yeloworld has been committed to green and low-carbon sustainability, focusing on packaging products. It has been a pioneer in introducing the circular economy into the petrochemical industry, supporting the industry’s sustainable development, and has become one of the formulators of the industry standard for plastic flat pallets in the petrochemical sector. As of now, Yeloworld’s pooling packaging has reached 4,000,000 pieces, with a cumulative total of tens of millions of packaging cycles. It has served over 300 clients and signed annual service agreements exceeding RMB1 billion.

Yeloworld’s Collection of Pooling Packaging

Focused Exclusively on the Petrochemical Industry

Building the Yeloworld Service System Through Plastic Reduction, Recovery, and Remodeling

From plastic pooling packaging to the plastic circular economy, every step of Yeloworld’s growth is deeply rooted in the pursuit of sustainable development. From a production perspective, Yeloworld has established green intelligent factories, utilized clean energy, and introduced automated production lines to enhance capacity. In terms of product design, the lifecycle of Yeloworld’s pooling packaging can reach 5–8 years, prioritizing longevity. Under the premise of ensuring performance, lightweight designs are employed to reduce energy consumption. For example, the weight of the 1311 pooling pallet has been reduced from 45 kg to 37 kg, resulting in a plastic reduction of over 17%. From a business model perspective, Yeloworld adopts a sharing model for plastic packaging, enabling its reuse within the petrochemical industry. Regarding resource utilization, Yeloworld recycles waste plastic products generated by itself and its partners, transforming them into recycled materials or packaging, embodying plastic recovery and remodeling. In terms of big data management, it promotes third-party carbon emission testing, provides carbon reduction data, and establishes a traceability system for low-carbon raw materials.

At present, green and low-carbon development has become a global trend in economic development. Yeloworld continues to enhance its capabilities, vigorously promoting digital and intelligent transformation as well as green transformation, empowering the petrochemical industry’s transition to low carbon, circular reconstruction, and digital transformation.

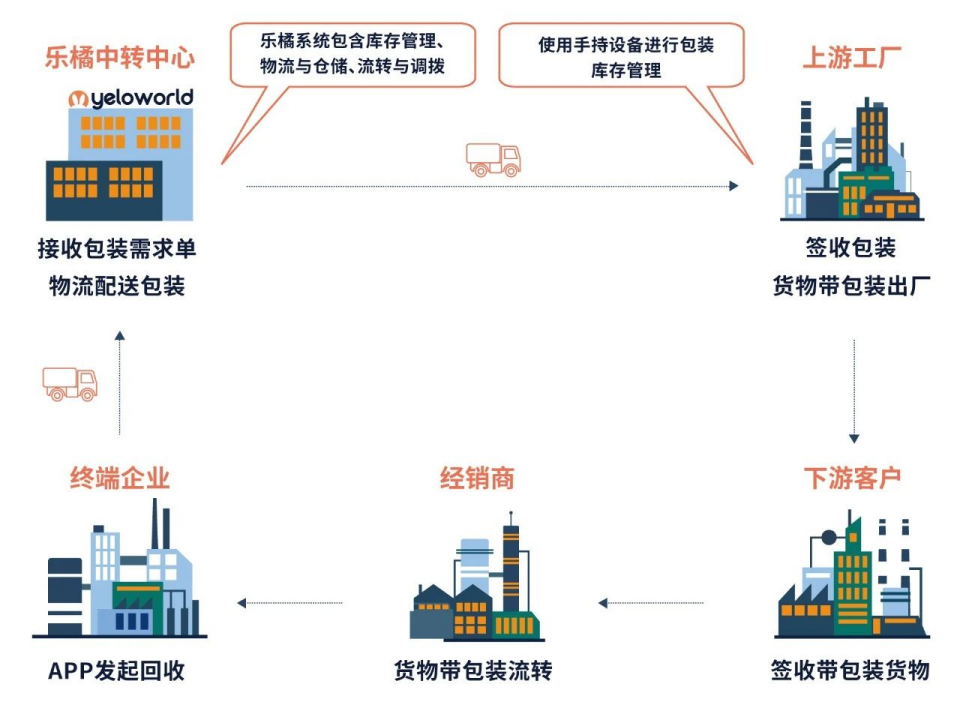

Yeloworld’s Pooling Packaging Operation Model

In-depth Analyzing Industry Pain Points

Providing a Full-chain Carbon Reduction Solution for the Petrochemical Industry

Driven by demand, we provide services that lead to changes. In the era of carbon dioxide emissions and carbon neutrality, reducing global carbon emissions has become a consensus, with various industries exploring collaborative efforts together to achieve this goal. As a dedicated pooling packaging service provider for the petrochemical industry, Yeloworld offers comprehensive plastic solutions across the entire supply chain.

In the traditional logistics and warehousing packaging sector, issues such as loose packaging transportation, repeated handling, high rates of cargo damage, inefficiency, and high costs have become increasingly prominent, leading to an inability to meet the demands of modern, efficient production and transportation systems. Yeloworld empower its packaging products through standardization, scaling, digitalization and intelligence. Based on the utilization of flat and stereoscopic warehouses in enterprises, handling equipment, packaging demand, inventory, and recycling volumes, as well as the transportation routes of goods with packaging, Yeloworld utilizes chips and positioning modules in conjunction with its proprietary big data platform to achieve cargo flow tracking, information management, and enhancing efficiency while reducing costs.

Furthermore, as a production-oriented petrochemical enterprise, collaborating with Yeloworld can create a plastic recycling and regeneration system for the waste plastics generated during its production and operation, ensuring the practical reuse of resources, demonstrating corporate social responsibility, and empowering brand value. Yeloworld’s closed-loop ecosystem for the plastic circular economy does not depend on slogans; rather, it drives the industry’s green transformation through practical and effective solutions.

Plastic Circular Economy Model of Yeloworld

The petrochemical industry serves as the foundation and cornerstone of China’s national economy. Embracing sustainable development, pursuing low-carbon emissions, and reducing pollution showcase China’s strength in green carbon reduction efforts on a global scale. Yeloworld has repeatedly secured funding from leading enterprises in the petrochemical industry, which reflects the concrete steps China’s petrochemical industry is taking towards green development. In the future, Yeloworld will uphold this trust and mission, integrating sustainable development with business models and balancing economic benefits with ecological outcomes to contribute more green solutions to the industry.

More

-

Yeloworld Won the 2024 China Green Point—Green Pioneer Award Initiated by YICAI

2024-10-01 -

Hainan Yeloworld Super Factory Phase I Officially Launched, Expanding Presence in South China

2024-09-25 -

Yeloworld’s Sixth Anniversary | Creating a Greener World with Passion, Bringing Dreams to Life Through Action

2024-08-09 -

Yantai Super Factory Officially Goes into Operation! We Break Through the “Last Kilometer” of Pallet Transportation

2024-06-13 -

Yeloworld Ranked Among the Top 20 in the Second Shanghai Green Technology Innovation Competition 2023

2024-03-22