The First Intelligent Pooling Packaging Forum 2020 Successfully Held

On May 15, 2020, the inaugural Intelligent Pooling Packaging Forum was held in Shanghai, hosted by Shanghai Yeloworld Technology Co., Ltd. and co-organized by Shangnan Pallet Sharing. Attendees included representatives from numerous prominent domestic and international chemical companies, such as the China Federation of Logistics & Purchasing, Sinopec, BASF, Dow Chemical, Huntsman, Covestro, Lubrizol, Evonik, Wanhua Chemical, SECCO Petrochemical, and Owens Corning, along with leaders from various industry associations. The forum aimed to foster deeper cooperation in intelligent pooling packaging.

The First Intelligent Pooling Packaging Forum 2020 Kicks off

This forum was structured around three main topics: an introduction to intelligent pooling packaging operations, case studies from representative enterprises, and an enterprise roundtable discussion.

At the start of the forum, Shi Xiang, General Manager of Yeloworld, provided a comprehensive overview of the development history and operational model of intelligent pooling packaging. Since launching Yelopack in 2017, Yeloworld has built a shared pallet platform focused on circulation and reuse, supporting a unit-based logistics vision. This platform offers intelligent, convenient, and comprehensive supply chain solutions for companies like Sinopec and PetroChina. Yeloworld’s smart shared pallets, enabled with RFID and IoT technologies, address challenges in pallet management, tracking, and circulation. Today, Yeloworld manages nearly 400,000 pallets, serving a client base of 1,125 companies.

Shi Xiang noted that following the global outbreak of COVID-19, demand surged for Yeloworld’s independently developed shared packaging solutions, including Yelopack and Yelotour. With the rising need for intelligent pooling packaging, enterprises increasingly recognize its role in driving cost efficiency, standardizing logistics assets, and minimizing resource waste. This forum was established by Yeloworld to address the urgent need for cost-saving and efficiency solutions during the pandemic, and to engage in collaborative discussions on the shared ecosystem of intelligent pooling packaging with industry associations and supply chain partners.

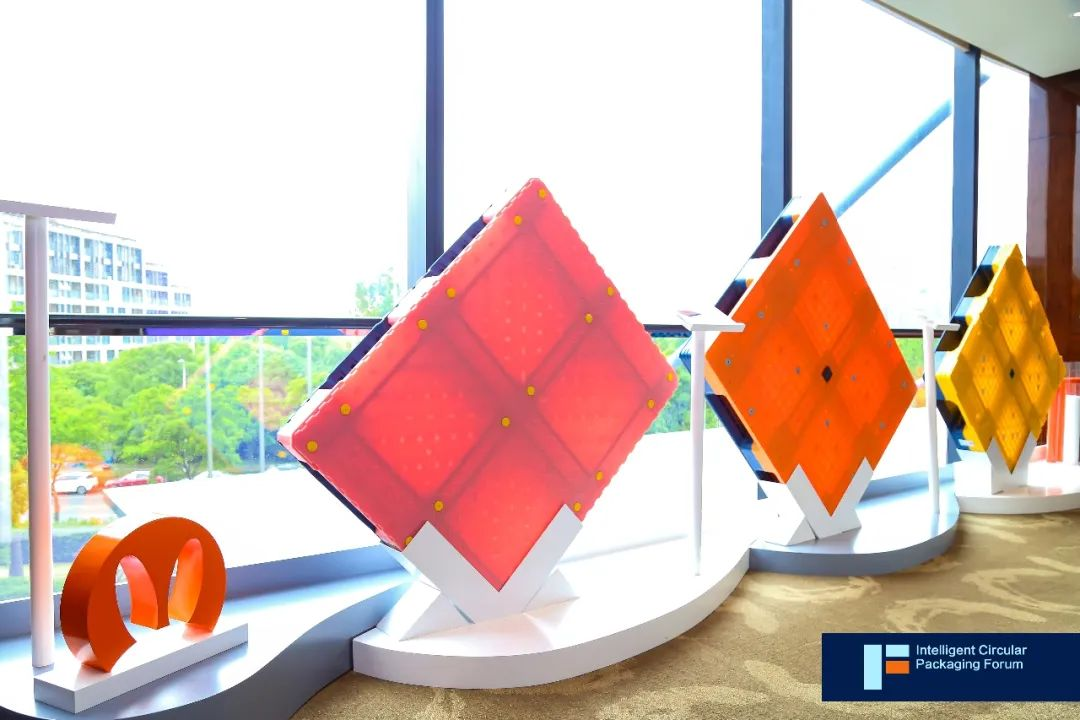

RFID-equipped Yeloworld Smart Shared Pallets on Display at the Forum

Among the speakers, Chen Long, Chief Engineer of Fujian Refining & Petrochemical Co., Ltd., shared insights as a representative user of Yelopack. He highlighted how Yelopack has driven a comprehensive transformation at the Fujian Petrochemical plant across packaging, warehousing, transportation, and loading processes. Traditional manual handling has been replaced by palletized loading and unloading with forklifts, significantly reducing labor costs. The loading time for an average 30-ton shipment has decreased from one hour to just five minutes, greatly enhancing logistics efficiency. This advantage proved especially valuable in the post-pandemic period, when manpower was limited, and the risk of infection was high.

Following this, representatives from BASF, Dow Chemical, Huntsman, Covestro, Lubrizol, Evonik, and SECCO Petrochemical, among others, engaged in in-depth discussions. They shared unique strategies focusing on the current state of packaging, future prospects for intelligent pooling packaging, and ongoing efforts in cost reduction and efficiency improvements.

Covestro Group representative Cai Bijiao raised a compelling discussion on intelligent pooling pallets and the circular economy’s growth. As early as August 2019, the Opinions on Accelerating the Development of Circulation to Promote Commercial Consumption, jointly issued by the General Office of the State Council and the National Development and Reform Commission, explicitly encouraged the development of “Internet + Resource Recycling” to promote circular consumption. Compared to traditional wooden pallets, Yeloworld’s shared pallets excel in material durability, usage cycles, and ease of cleaning and recycling. Yeloworld’s intelligent pooling packaging model aligns closely with the “Internet + Resource Recycling” approach from the National Development and Reform Commission. In the long term, intelligent pooling packaging offers considerable cost benefits and sustainable potential.

Guests Engage in In-depth Discussions on the Intelligent Pooling Packaging Model

Zhang Hong, a representative from Shanghai SECCO Petrochemical Co., Ltd., emphasized the transformative impact of shared pallets on the chemical industry supply chain. As one of the earliest adopters of Yeloworld’s intelligent pooling packaging, alongside Fujian Petrochemical, SECCO’s expanding downstream market has driven terminal factories and distributors to deepen their understanding of shared pallets, gradually establishing a standardized and efficient tray transfer system.

During the forum, participants thoroughly discussed topics such as new materials, cleaning standards, and value-added services for intelligent pooling packaging. Many representatives expressed a strong interest in pursuing further collaboration with Yeloworld, aiming to promote high-quality logistics development in the chemical industry and establish a shared model for intelligent packaging.

Group Photo of Guests at the First Intelligent Pooling Packaging Forum

The success of this forum signifies major advancements in Yeloworld’s collaboration with industry associations and partners in developing intelligent and digital solutions for shared packaging. This event also provided a multi-dimensional approach to help companies reduce costs and enhance efficiency amid the pandemic. With the combined efforts of all parties, intelligent pooling packaging is set to achieve significant progress.

More

-

Yeloworld Won the 2024 China Green Point—Green Pioneer Award Initiated by YICAI

2024-10-01 -

Hainan Yeloworld Super Factory Phase I Officially Launched, Expanding Presence in South China

2024-09-25 -

Yeloworld’s Sixth Anniversary | Creating a Greener World with Passion, Bringing Dreams to Life Through Action

2024-08-09 -

Yantai Super Factory Officially Goes into Operation! We Break Through the “Last Kilometer” of Pallet Transportation

2024-06-13 -

Yeloworld Ranked Among the Top 20 in the Second Shanghai Green Technology Innovation Competition 2023

2024-03-22